|

|

|

FOR TWIN TAIL TYPES |

20 amp AC breaker for 24 volt systems

40 amp AC breaker for 12 volt systems

30 amp AC breaker for 24 volt systems

50 amp AC breaker for 12 volt systems

BATTERY CONTROLLERS INFO

BATTERY CONTROLLERS INFO

TURN OFF ALL ELECTRICITY BEFORE

MAKING ANY

TURN OFF ALL ELECTRICITY BEFORE

MAKING ANY

Slip Rings are not the correct technology for small

wind turbines.

Slip Rings are not the correct technology for small

wind turbines.

To replace the slip rings in your old wind turbine or to install one of ours you will need two pieces of 6# welding wire, one red and one black. This will go inside the pole tower and can withstand lots of twisting and turning motion.

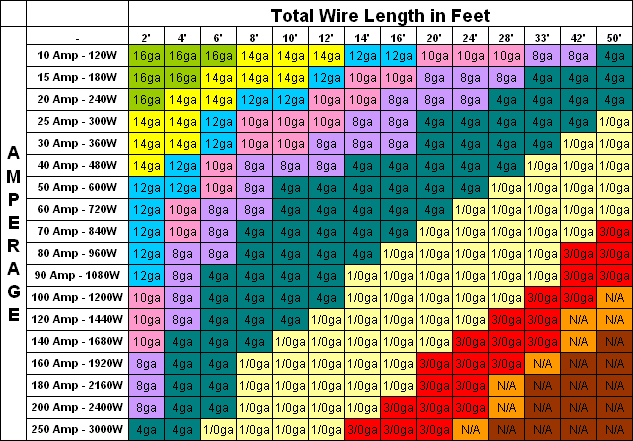

Is #6 AWG wire large enough for your lateral wire run?

Maybe not if you have a long run.

"Carbon brushes wear out, sooner or later but most often they fail by snapping like ice sickles in any

freezing weather and those are just a few of the cold hard facts against the use of carbon brushes in general"

OTHER TOWER IDEAS USING WOOD FRAME